The 50-250mm Fully Automatic Purlin Machine is an advanced industrial equipment designed for efficient production of high-quality purlins. With precision engineering and full automation, this machine effortlessly shapes metal sheets into precise and uniform purlin profiles ranging from 50mm to 250mm in size. Its versatility allows for various specifications of purlins, meeting diverse construction needs. The 50-250mm Fully Automatic Purlin Machine ensures consistent and accurate results, optimizing production efficiency and reducing manual labor. It is an essential tool for manufacturers aiming to deliver reliable and durable purlins for commercial, industrial, and residential buildings, providing superior structural support with seamless automation.

The Algerian customer need machine to produce 50-250 mm width and 3mm thickness product. He will use the product make the warehouse structure and solar panel strut. Because there are strong wind in Algeria area, so the purlin must be thick, thickness up to 3mm.

The machine picture for reference:

3mm thickness finished product for reference:

50-80mm width use for the solar panel strut:

80-250mm use for the warehouse structures:

How to adjust the machine when thickness changes?

For example from 1.5 to 3.0mm. If the thickness of the replacement material does not exceed 0.5mm, such as changing from a material with a thickness of 1.5mm to a material with a thickness of 1.8mm, there is no need to adjust the machine. If the thickness change exceeds 0.5mm, it is necessary to adjust the gap between the upper and lower rows of forming rollers of the machine. If the thickness increases, the gap needs to be increased, and if the thickness decreases, the gap needs to be reduced.For example from 1.5 to 3.0mm, you need to increase the gap between upper roller and lower roller of all the stations. Use a ruler to measure the gaps and make it increase by 1.5mm.

How to adjust the sizes by PLC operation? Expect PLC setting what other work we should do?

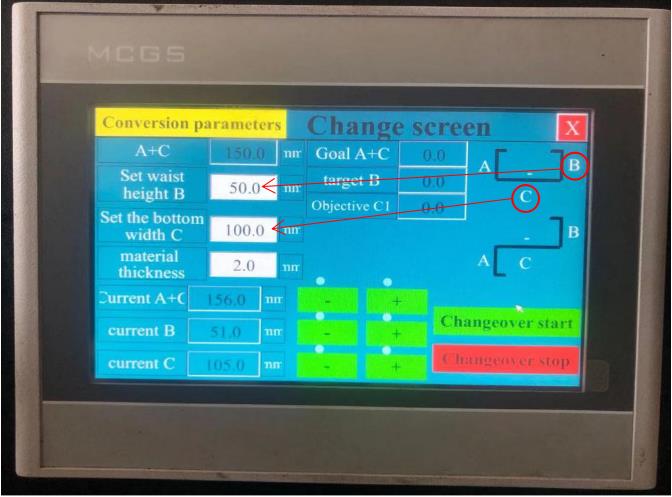

Input the height and bottom width of the product you want to change and the thickness of the material used in the white background input box on the screen, click changeover start, and the size adjustment motor starts to automatically adjust the roll forming parts to the required position.

Then you need to manually adjust the hand wheels on both sides of the feed inlet and vertical guide wheel between leveling and punching unit to adapt to the adjusted feed width.