0.3-0.8mm Thickness Trapezoid Roofing Sheet Roll Forming Machine Hot Sale In Dominica

Purpose:

Trapezoidal roof tiles are mainly used for roof decoration, exterior wall decoration, and strengthening roof strength in civil and industrial plants. Using it on the roof can make it more aesthetically pleasing and enhance its rigidity and waterproofing; When used on the exterior wall, it can make the entire factory more beautiful, prevent the exterior wall skin from falling off, and provide insulation against the cold.

The advantages of this machine are:

- Ensuring product quality:

Through precise mechanical control, the trapezoidal roof panel machine can ensure consistent quality of each panel, avoiding potential quality fluctuations during manual production. - Design flexibility:

The0.3-0.8mm Thickness Trapezoid Roofing Sheet Roll Forming Machine usually supports customization of multiple specifications and sizes, and can adjust production parameters according to project needs to meet the requirements of different building designs. - Material adaptability:

The 0.3-0.8mm Thickness Trapezoid Roofing Sheet Roll Forming Machine can handle different types of metal materials, such as galvanized steel plates, color coated steel plates, etc., suitable for the anti-corrosion and decoration requirements of different building projects.

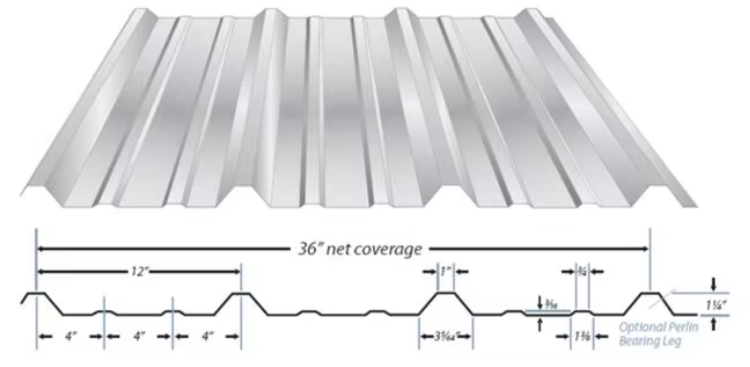

Profile drawing :

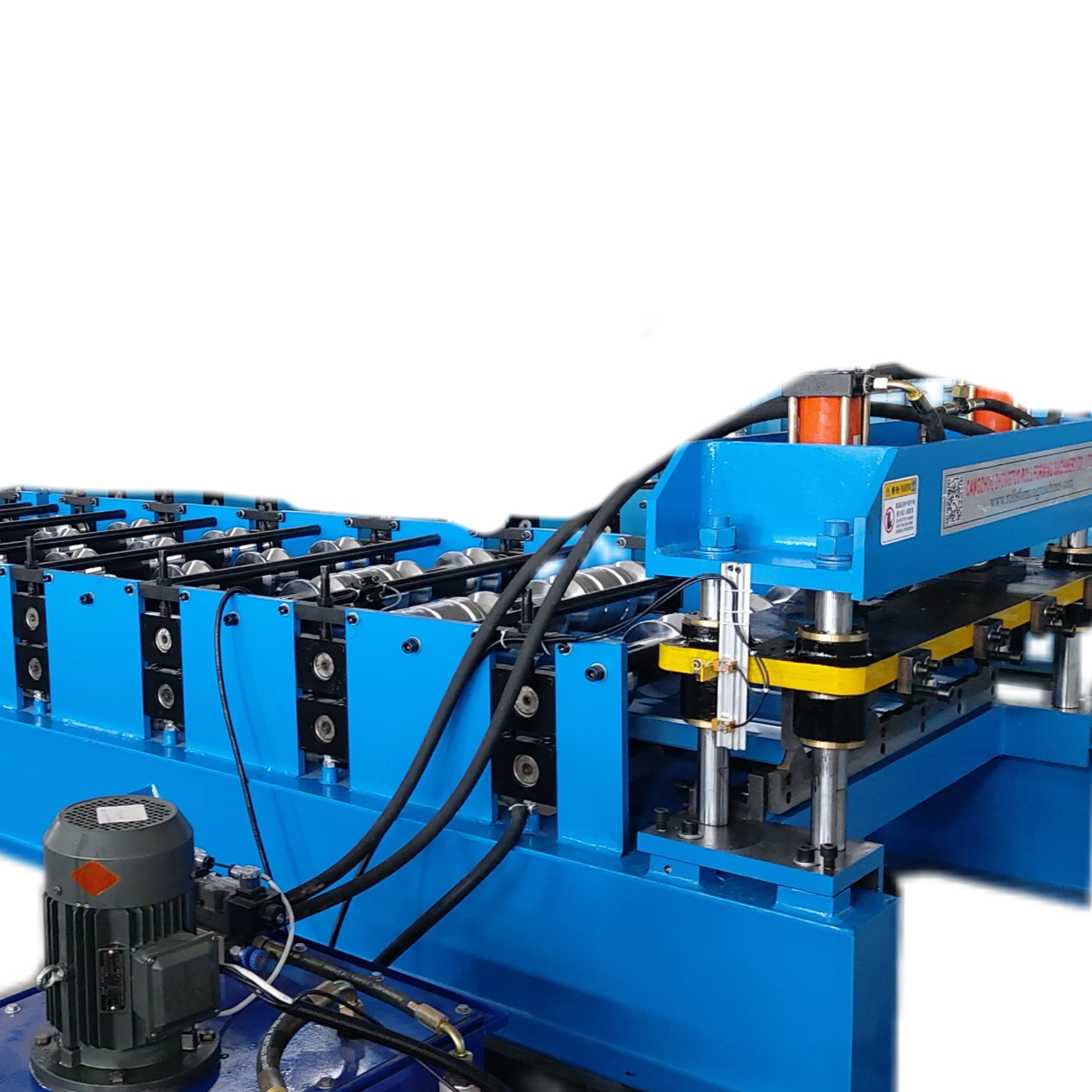

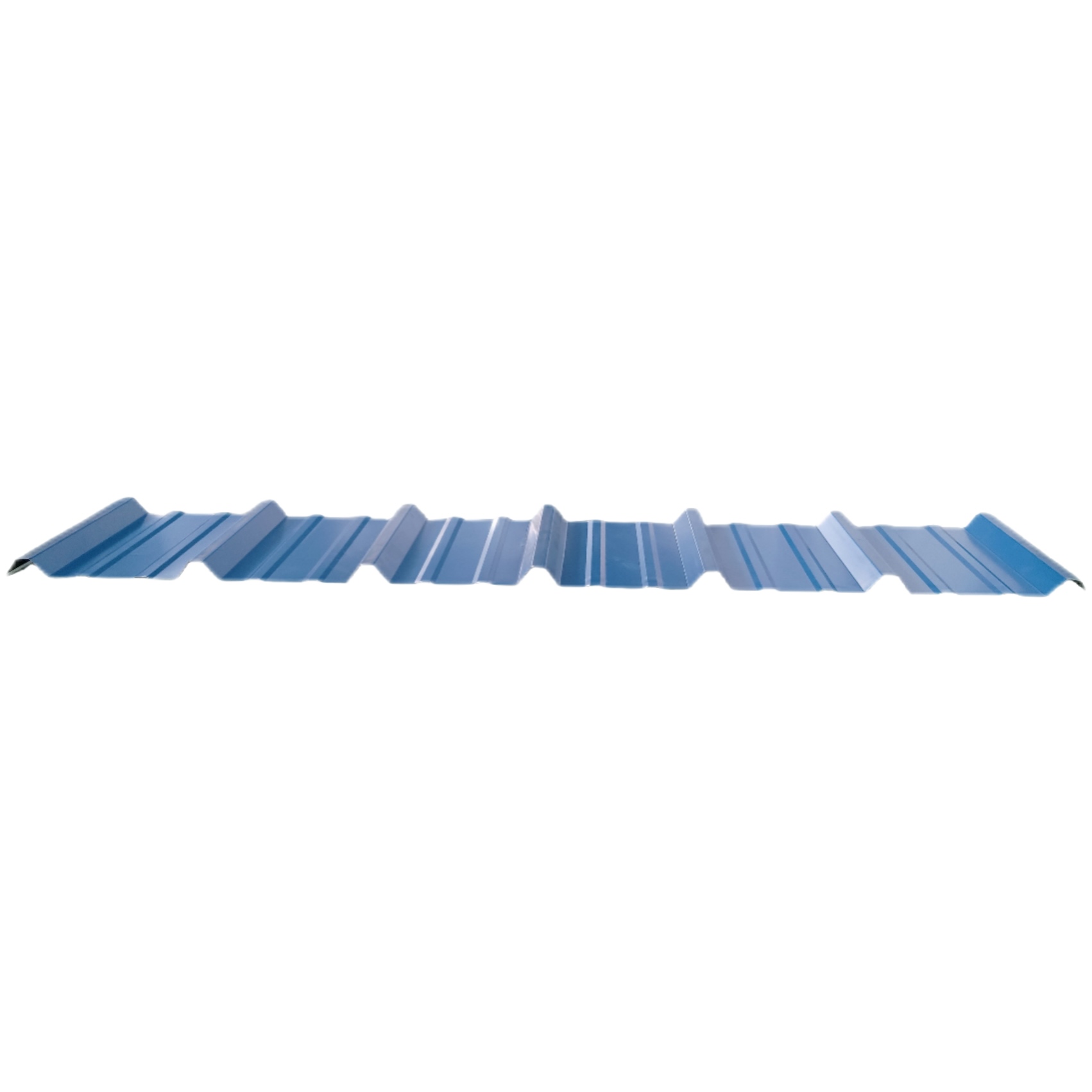

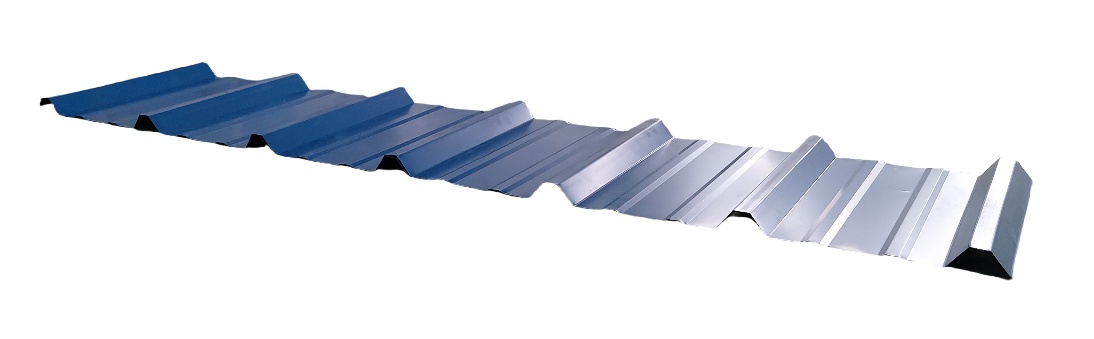

Here are photos of 0.3-0.8mm Thickness Trapezoid Roofing Sheet Roll Forming Machine:

The technical specifications of 0.3-0.8mm Thickness Trapezoid Roofing Sheet Roll Forming Machine:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.3-0.8mm Width:customized

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

15rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

6.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||